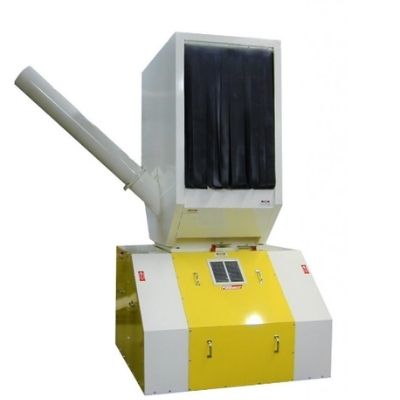

Foremost Heavy Duty Granulator HD-8

The HD-8 scrap grinders are specifically designed and built to granulate either large parts or high volumes of scrap material. With its large throat size of 24″ x 36″, offset cutting chamber and rugged construction, large molded parts can be readily granulated without the need for pre-cutting.

It is an ideal machine for applications such as post-consumer scrap recycling when equipped with our optional high throughput rotor and screen package.

The scrap grinder features a standard two-bladed hook knife rotor with a full series of optional, application specific rotor designs for optimal performance. All rotors are double end driven with dual belt driven flywheels supported by heavy duty, sealed roller bearings.

The offset position of the rotor in a completely welded cutting chamber provides bounce-proof, positive cutting action.

The standard unit is equipped for hand feed or conveyor feed operation with a blower discharge chute. A full range of standard and custom configuration options are available to fit the user’s application requirements.

The Model HD-8 grinder has a proven record of long, reliable service in a variety of applications. Let our 45-plus years of grinder manufacturing help solve your size reduction problems.

- Offset rotor.

- Self-aligning flanged bearings.

- Hand feed hopper with access door.

- Powered by two single end motors.

- Large blow molded parts.

- Large injection molded parts.

- Extruded profiles.

- Recycling post-consumer waste.

Reviews

There are no reviews yet.