Maguire IBC & Layflat Control

IBC & Layflat Control

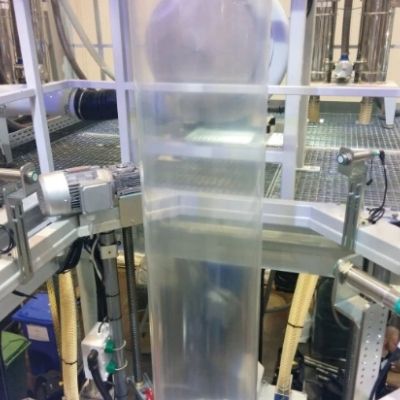

Internal Bubble Cooling (IBC) is designed to automatically control and manage blower balance and increase cooling efficiency.

- Non-contact, ultrasonic IBC bubble control

- Precise layflat control

- Waste reduction during start-up and changeover

Another critical factor on from materials blend and extrusion control for the performance of a blown film line is the IBC (Internal Bubble Cooling), with integrated auto width control for the layflat.

Upgrading a line without IBC & Layflat Control, or a line with a dated simpler system can deliver significant performance benefits for any blown film line.

Maguire + Syncro offer SYibc, which is a convenient and effective package for IBC and automatic Layflat Control. A processor can upgrade as a standalone product or integrated as part of the program of modular upgrades for improving performance on a blown film line from Maguire + Syncro range of products.

To enable fast and accurate control of a layflat width the SYibc uses a triangulation of 3 non-contact ultrasonic sensors, with a separate calibration sensor to moderate for ambient conditions. This data provides constant readings to the IBC PLC control, and enables the IBC stepper-controlled valves to be precisely regulated for fast and consistent control of the internal bubble cooling airflow.

Upgrading your line with Maguire +Syncro SYibc can quickly deliver these core benefits:

- Improved control and increases production rates.

- Optimize layflat control to less than ± 2mm of target set for LayFlat width control.

- Increase internal cooling rates – increases production and process consistency.

- Edge trim and startup waste reduced – reducing materials costs.

- Reduce manual interventions and setup.

- Easier product changes and quicker setups and startups.

- SYibc applicable for all types of IBC die, EasyWidth for non IBC – compressed air dies.

- Temperature compensation manages 24-hour ambient fluctuations.

- Cost effective to deploy – typical return of investment within 12 months.

Ultrasonic Layflat Sensors

- Optional ultrasonic distance sensors.

- Mounted on top of cage where bubble is already formed.

- Controls automatic opening & closing of cage.

- Improved layflat width control to less than ± 2mm.

Ambient Temperature Control

- Ultrasonic sensor installed at a fixed distance.

- To control ambient temperature variations.

Ultrasonic Gap Sensors

- Mounted on bottom of the cage.

- Maintain distance between bubble and moving cage.

- Measure instant bubble dimension variation.

- To avoid deflation of bubble.

IBC Control Valve

- Unique bypass valve to improve flow control.

- Valve installed on T pipe.

- Improved accuracy in bubble stability.

- Customized stepper motor.

Maguire + Syncro Control Flexibility

- Convenient operation and analysis via Syntrol Plus Supervisory System.

- Rapid detection and response for optimum width stabilization.

- Waste reduction.

- Improved bubble stability.

- Faster and simplified operator control.

- Possibility to store all key process setup parameters.

Reviews

There are no reviews yet.